The relationship between centrifugal pump flow channel loss and impeller

The main mechanical loss of the centrifugal pump is the increase in the friction and loss of the pump disc, which is basically 30% of the effective power; if it can reduce the dedicated area, the roughness of the impeller and the pump, it can be greatly reduced. The loss caused by friction, based on the reasons mentioned above, the use of ultra-slip coatings or the use of more advanced smooth impellers can also directly reduce the power loss of pipeline pumps during operation.

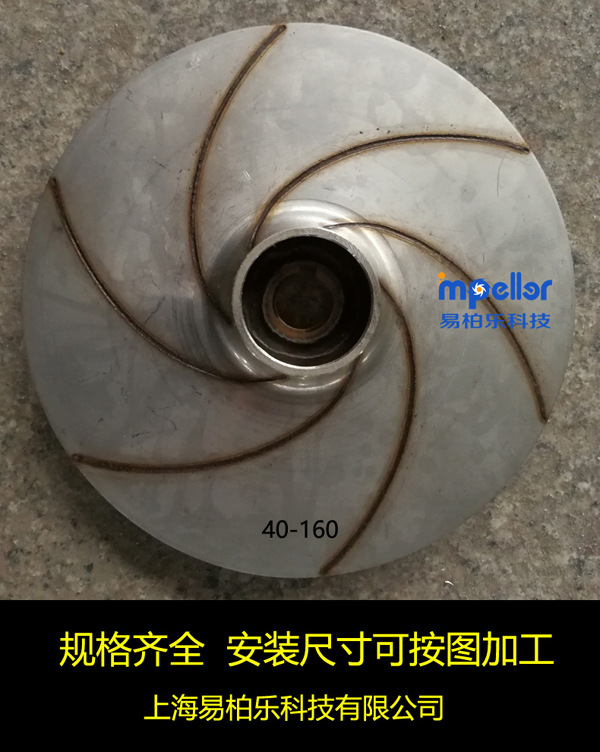

But when we use it for a long time, and the erosion of various sediments and water flows, the impeller is slowly worn and corroded, and the surface is formed with grooves and scratches. Sometimes the industry will be damaged by the air, and the two will appear differently. Kind of honeycomb or perforation, no matter if some are not handled properly during casting, with pores or debris mixed in, there will be pores or cracks after a long time of use.

There are many repair methods for impeller damage of centrifugal pipeline pumps, such as spray welding, and many stainless steel inlay or welding. The use of epoxy resin polymer material coating has the advantages of simple construction method, low price, and good effect. By optimizing the ratio, the performance indicators of the materials are adjusted in a targeted manner, showing high-strength adhesion and toughness for absorbing impact energy, with high strength and hardness against cavitation and abrasion damage.